The Tools and Toys page.

Welcome to my Tools and Toys page.

On

this page I will display my new tools, toys and other gizmos that I

buy or fabricate. Yeah, I know it

might be considered a little

”show off”, but I think it can be useful for people

looking for ideas for stuff,

or want a review on stuff they think

about buying.

Remember, all opinions expressed here are mine.

This is how I do things, how I feel about things, and

what I think

about stuff. Your mileage may vary.

All pictures are clickable

for a larger version of them.

So

far this page contains the following:

1. Welder.

2. Workbench.

3. Welding helmet.

4. Hole saw set.

5. A Creeper.

6. Engine leveler.

7. Hammers and dollies.

8. Body jack.

9. Bending brake.

10. Slide hammer.

11. Some air tools.

12. A new vise.

1.

A new welder.

At

last I got myself a new welder. Well, not a new one, a second or

third hand one. It was

practically given away so I just couldn't

resist it as it was of my favorite brand ESAB. It's a 200A

three

phase machine, model Power Compact 200. Pics below.

The

new welder. Weight about 170 pounds and I loaded/unloaded it by my

self. Ouch!!

I

did a short test run with it as soon as I got a bottle of gas for it,

just to make sure it was okay,

and thought it ran quite well.

Now,

after welding a bit with it, I must say that this is the best welder

I ever used!

It welds very smoothly with almost no spatter and

the burn-in is just perfect. Nice even welds

that look perfect,

even when seam preparation isn't perfect. Wow!

This

welder beats everything I worked with earlier and that includes but

is not limited to all the

welders listed below.

Kemppi Kempomat

150 – This one is simply too weak. Had problems even with sheet

metal.

Kemppi Kempomat 163 – Better than the one above but

too “hard” in its characteristic.

Kemppi Kempomat 253

– Pretty good welder, fairly smooth but likes to burn through

material.

Miller MillerMatic 250 – A really nice welder.

Almost as good as the Esab PC200. But not quite.

Esab LDM 300 +

A10 – This is an industrial welder. Very nice, but too big for

the stuff I do now.

Esab Smashweld 180 – Good welder for up

to 1/4” and sheet metal. A little rough characteristic.

So, if you're shopping for a welder, take a close look on the Esab Power Compact 200!

2.

A new workbench.

I've

also cleaned up a bit in the garage and built a new work bench today,

including a new vise.

This is a thing I've wanted to do for a long

time as I have felt the need for a place to do slightly

heavier

stuff than fixi'n up a fender or two... Now, if I only could figure

out how to double the floor

space everything would be

honky-dory...

My new workbench. Had to keep it small, just

2' by 6'. Bolted to wall and floor.

I built

the workbench from 3x2” wood, and it's put together with screws

and steel brackets. Maybe

not the most beautiful workbench but

plenty sturdy and will do the job all right.

It came out a little

too high, but that's better than too low. Easier to fix anyway.

3.

A new welding helmet. As

I got the new welder I thought a bit about getting one of those new,

shiny, bright thingies for

eye protection that automagically get

dark when you start to weld. The ones I have seen before

have

been extremely expensive so I did hesitate a little. Good thing I did

that, because now I found

one at a very fair price, and I bought

it of course...

The

Optech S-998 that I got is actually very good when you get it dialed

in right. It's quite easy to

adjust and works like a charm. The

only thing I find a bit annoying is the adjustment for force needed

to tilt the helmet up and down. It has a little ”made in

China” feeling, but at the price it is going for I can

live

with that. Just the feeling of having both hands

free makes this a good buy!

4.

A hole saw kit.

This

is a must have for any one doing metal work. I found this kit on sale

at 50% off, and I can tell you

that it really mattered... I would

never have bought it at full price. Bahco tools are top of the line

quality

and they don't come cheap!

The

hole saw kit. The empty slots are supposed to be there...

5.

A Creeper.

I

dont know how I managed without one before... But that can be said

for all of the stuff on this page.

No more freezing my butt off on

that cold concrete floor. No more throwing blankets on that dirty

concrete floor either.

This

”Big Red” creeper is very soft and comfy to lay down on

and really invites you to fall asleep. It also

folds up to a nice

comfy shop chair right when you need one, so that's a big plus also.

The only things I

think is a little ”el cheapo” are

the wheels as they want a flawlessly smooth floor to roll easy.

Anyhow, I like it!

6.

Engine leveler

This

is a tool I considered a pure luxury and a bit of a ”sissy

tool” before. No more so. I recommend it

to anyone that will

do an engine and tranny swap more than once in a life time.

This

is also a ”Big Red” tool, and the quality is quite okay

for the price of it. A really great helper to

get an egine and

tranny combo angled right to get them in smoothly without damage to

either the

engine compartment or your back.

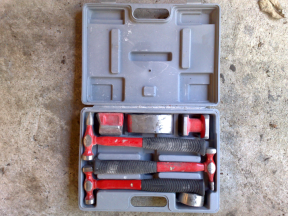

7.

Hammers and dollies.

These

are just a must when working with sheet metal! There's no way around

it, a set of hammers

and dollies pays for them selves at least

one time every dent you use them on. This set was cheap

and of a

little suspicious quality, but they have saved the day more than

once.

As you can see in the picture these have been used extensively both

on my own rigs and others.

Actually I prefer hammers with a

wooden handle, but considered the difference in price I can live

with

the slightly off-balanced fiberglass handles.

8.

Body jack.

A

body jack is a good thing to have when dealing with a little larger

sheet metal damages. Like

when I rear-ended a cop car with my old

ambulance... If you know how to use it, and know how

sheet metal

behaves under preassure, you can do almost anything you'll need with

this one.

This

is a 4 ton unit which is enough for about anything except to

straighten a frame. For that there

is a 10 ton unit which is much

heavier and thus much harder to handle. When I need a 10 tonner

I'll

get one. I've worked this one pretty hard and it has help up well.

9.

Bending brake.

A

bending brake is a good thing to have when working with sheet metal.

I just got one and it has

already been in use quite a lot. This

thing saves time when making body panels. Capacity of the

brake

is 0.6 mm at full width according to the spec sheet, but I bent

double that thickness at not

quite

full width more than once without any problems. Maximun width is 710

mm.

Yes, it was cheap. But it works pretty well and

the quality is pretty good for the price price I paid.

The only

thing I don't like about it is that the handles are just pushed in

and not secured in any way.

The possibility of the handles

slipping out while bending is not that big, but you have to make sure

they're seated well every time you use it.

But as I always

say, you get what you pay for, so I shouldn't complain. The better

version of this

brake is three times the cost, and not worth it

considering how often I use it.

10.

Slide hammer.

The

perfect tool for pulling dents. Well, hand tool that is. The ultimate

tool would be a body jig with

lazer measurments and hydraulic

pullers, but that's a bit out of my league (yet).

Another

cheap, made in China, tool that I got. But hey, it does the job it's

supposed to do and there

isn't many things that can break on a

thing like this. It comes with a one year warrantee and if it

breaks

within that time I get a new one. If it breaks after that, I guess I

have to shell out another $12.50

for a new one.

It comes with

a two soft sheet metal hooks (they suck, too soft), two round steel

hooks that are some

what useful, and two screws (one straight and

one tapered). The two soft sheet metal hooks are best

used as

”weld on” and pull dent. That's the way I use this tool

anyway so it's not a big deal.

11. Air tools.

Some air tools are never a wrong thing to have. A half inch impact gun, a 3/8 inch air wrench, and a disc sander is

what's in the picture. Missing in the picture are the jackhammer, the sheet metal shears, and the paint guns.

I would have preferred to get Ingersoll & Rand air tools, they're the best, but they're also too expensive. So, I

had to go for the cheaper line. Not the cheapest though, I've got one real cheap impact gun and it blows. Never use

it anymore as I got a better one too...

12. New vise.

Had to get a new vise as the old one cracked. This time I got one that is of forged and heat treated steel, not

just cast iron. I'll see if I can find the receipt of the old one and get a refund. If not I'll try to weld it

with some nickle rod and use it for light duty work.

So far I'm very happy with this new one, it has done all I ever wanted of it. Though, the price was three times

the old ones. You get what you pay for...

That does it for this update.... More to come soon!!