From junk to a daily driver.

Here

are some pictures of the journey of this old ambulance. I'm currently

rebuilding it to use as

a daily driver, and I will try to get it

on the road as soon as possible. I bought it in July 2005, outside of

Örebro some 350 miles from home. The trip with this beast on

the trailer was not the funniest ride

I ever had....

But let's not get ahead of things. First, a picture of how it looked

once, while still in service. The

picture does not show this

actual vehicle, but a “sister vehicle”, same year and

same company

that made the high top. Looks nice, eh?

Photo

by: Willhelm Wahrenberg

So, lets take a look-see on how it

looked when I first found it.

It had just been standing there for

25 years....

Hmmmm..... Do I really want this? Let's look some more!

Eeeuuuwwww... Y'all think I need therapy?

Okay, so it needs a washing. And some

new sheet metal. And a diesel engine. And some more....

But when I

finally got it home, it looked a lot better. I'll tell you that

getting it on the trailer was a

hellish task. One brake locked

up, winch wire busted, the tractor used to pull it up broke down...

But finally we got the beast loaded.

Maybe a tad of an overload according to Swedish regulations

but we

got it home okay. This is what it looked like:

On

our way home....

In the following pictures it finally has arrived at its new home.

Just

unloaded the bugger.... Looks nice though, don't it?

Before we start to do things, let's

see what we really got. A copy of the line setting ticket

is a

good place to start. Below is a scan of the ticket, with some VIN

numbers removed

because those are of no interest to the public...

This ticket is the key to about

everything on the vehicle. There are no ”standard” IH:s,

and

the linesetting ticket clearly tells what parts were used to

build this specific vehicle.

A good thing to have if spareparts

are needed!

Now the real work starts.

So,

lets start tearing it apart. Finding rust, contemplating, and finding

some more rust....

Engine

out, and mom inspecting my work. All she saw was rust....

Well, after washing and touching up

the engine bay and frame it was time to take the old lady inside

(not mom, the IH). Time to do something about the engine. The old

BG-241 went out, though it

was in good condition, and a GM 6.2

litre diesel V8 went in. The T-28 BW auto trans was

replaced with

a TH700R4. Me likes overdrive!

Before...

After...

Nice

thing about the swap was that the length of both packages were equal,

so I don't have to

customize the length of the drive shaft. The

front U-joint on the IH drive shaft fits in a TH350 slip

yoke,

and the TH350 slip yoke fits the TH700.

No problems with

clearance, but I had to make a new tranny mount crossmember.

It looks

a bit of a mess, but that will be cleaned up later. Lets check the

supports for the engine

mounts... It's amazing what you can do

with a welder, some time, and a pile of scrap!

Engine

mount supports tacked in place. They are made of 2½

inch square pipe.

I don't

have the slightest idea of what the engine mounts are. Got them on a

swap meet and they

bolted right up! If anyone know what they are,

prey tell!

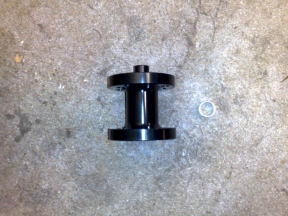

The drive

shaft really did not need any modification. I just had to add a TH350

slip yoke on the

existing front U-joint. Looks like this:

Front

part of drive shaft.

When I

have put it in place I'll probably put two small tacks in the splined

intersection. No need

to have it slide in two places, eh?

Okay, so let's take a lookie on the exhaust...

I can't say it was

easy to fabricate the right front downpipe. It was real tight and I

had to cut out a piece

of carrier for the original tranny

crossmember. But as it is not used anymore...

Well, over to

pictures,

Right

downpipe and collector of 2x2” to one 3”.

The left to right crossover pipe was fairly simple, just a couple of bends.

Crossover

pipe from the left to the right side.

I did say it was tight at the right side, didn't I? Let's have a lookie and see...

Collector

pipe. Had to cut out a piece of the tranny crossmember...

The rear parts were not really a problem. Muffler fitted just as if it was made for the ol' girl.

Middle

section mounted. Looks nice, eh? Muffler is a 3” straight

through.

Some welding and bending fixed the rear part quite nicely. Had to

drag it far to the right

because the spare tire hanger...

Got

it right over the rear axle too....

So, with engine in place it's time to pay some attention to reddish

brown cancerous stuff.

The left rocker panel was almost gone, the

right one could be saved but i cut that one out too. Much

to be

able to see what was going on the inside.

Right

rocker cut out.

The right one was in much better shape than the left one, and I only

had to replace the outer panel.

On the left side I also had to

replace the bottom of the rocker, and a piece of the outer wheel

well.

New

left rocker panel and rear outer wheel well. Lots of grinding to

do...

Another place where these babies tend to rust out is the front cowl.

Drain holes get clogged. In

this case the front fenders had been

repaired once before, and all drain holes where covered with

body

mastic... Wouldn't surprise me if it was done on purpose in hope that

the particular body

shop would get more to do.

Well, I had to cut open the front cowl on both sides and weld new

sheet metal in the bottom of it.

If not, rain water from the

ventilation channel would have been running right into the cab...

This is how it looks stitched together, after the surgery:

Right

front cowl, welded together again.

So, time to do something about the front fenders and the front. I cut

out the rusted pieces and

treated the minor rust attacks with

phosphoric acid. New sheet metal was welded in, and the

fenders

and front look pretty okay. Remember, it's gonna be my daily driver,

it's not a complete

resto job. :)

Front

patched.

The front

looked okay until it was removed. Then I found out that the bottom

cross member

was almost gone. Well, some pieces of angle

bent sheet metal took care of that. Then I cut out,

bent, and

welded in a fresh lower part of the front. Looks okay, I think.

So, what about the fenders? Let's take a look at them and see what had to be done...

Left

fender.

Not much to be done, except for the rear part of it. Cut out and

welded some sheet in the back

of it, ground down the surface rust

and treated it with phosphoric acid.

Right

fender, a lot more to fix on this one!

The picture isn't the best, but as you can see, there was some more

to cut and paste on this one.

I also had to rebuild the inner

parts of the fender almost completely. After grinding down the

tacks, I'll use body lead to shape it up. Lead is good, plastic

is baaaad....

Here's a pic of the complete right fender:

Well, it's been kinda slow the last week. But, I have de-rusted and

painted the inner front

fenders. A steel brush on the angle

grinder does marvels with the brown stuff! Then two

coats of

black Hammerite, and presto!

I've also started on the heating system, dropping in new hoses, and

started to clean up

the electrical system on the engine. Lots of

unneeded stuff, like EGR, EPR, TPS and

other stuff. Thought I'd

finish heating and electrical stuff before starting to assemble

the

engine compartment.

Finished up the wireing for the engine and tranny. Looks really good.

Everything is bundled

into one cable channel on the right inner

fender. There were some extra wires from the

engine, like the

glowplug light, water in fuel light, and the TCC wire. These were

wired

into the original IH wireing harness in those wires that

are obsolete for a diesel engine.

So, Here's a picture of the new engine wireing harness...

Right

side engine and lighting harness.

Thinking of the electrical stuff i found out that the Amp meter would

not cope with the

output of the alternator on the 6.2 litre diesel

engine. So I did it the easy way, I just

bypassed the gauge under

the dash. Here's a picture.

Amp

meter disconnected. The new lump of electrical tape is the wires

bundled together.

This also gave me one more unused cable, one of the feeds to the amp

gauge, for other

use. This one will be used as a + feed from the

brake pedal connector to the TCC.

I still have a problem though... I havent found a steering box yet,

and my time window

for getting one fitted is closing... mental

note Get one ASAP!!!

Picture below....

The

missing power steering box....

Well, the steeringbox isn't missing

anymore. After a lengthy quest I found a suitable box

at a local

junk yard. It's from a Mazda pickup. It was a bit shallow so I had to

cut into the

frame rail to get it down enough to fit the pitman

arm. Still gotta do the hoses and get

a nice steering column,

with tilt and maybe even telescope function...

Mazda

powersteering box in place.

The radiator is in place also. I had

to lower it ½” to let the lower hose get free from the

fan.

I also had to fab a new fan shroud as the fan on the 6.2 is a

lot bigger than the original one.

More work than I thought, but

the diesel needs a lot of cooling and the rad is a little

smaller

than I'd like.

Radiator

and fan shroud. Did some cut'n paste...

Next up is mounting the engine oil

cooler with its thermostat, then the tranny cooler. Just

got them,

nice, new and shiny...

Engine

oil cooler with thermostat, and tranny cooler. Cool! (pun intended)

While at it, I decided to do a little

more work.... I started fabbing the filler pipes for the

tank.

The old rubber hoses were rotted and dry, the piece of metal pipe was

rusted through.

So, I fabbed two new pipes from 2” exhaust

bends. One from tank to filler neck, and then

the filler neck.

Still have to cut the filler neck plate to shape, fix overflow, vent,

and return line.

Looks like this:

Left

goes to tank, filler neck (right picture) connects to top.

That does it for this week. Next week will be devoted to coolers and hoses...

Well, I've been lazy. But today I

finally got my butt out of bed and started on the coolers and

hoses.

The transmission cooler was a piece of cake, just sandwiching it to

the radiator with

the mounting stuff that was in the box. The

engine oil cooler was a bit more difficult, I had to

make my own

fixtures and the hoses were a pain to route. Here's pictures:

Transmission

cooler and engine oil cooler.

Lets see how it looks on the same picture, easier to see how it looks that way...

Front

picture showing both tranny and engine oil cooler.

I also did the rear brakes. I traded

the old BG-241 for a complete set of brakes, front

and rear.

Shoes, wheel cylinders, hardware kit, and a kit for the master.

Thought it was

a good deal since I was going to swap engine

anyway. Pics say more than words, so

here we go.....

Rear

brakes and rear drum.

The rear drums were in very good

condition so no turning is needed. I used high temp

copper paste

where I thought parts needed a bit of lubing. This has proved to be a

good

thing during the years I've worked with cars and trucks.

The next few days I'll use to hook up

the powersteering, and finish up the oil and water

hoses. Then

it's time to fill her up with fresh oil and coolant, hook up the

throttle and power,

and then it's starting time! Can't wait to

start her up!!

Well, maybe I'll have to hook up the tank first,

but after that.... smile

Okay, so today I hooked up the power

steering. And did some minor things like adjusting

hoses and

fabbing a bracket for the throttle wire... Powersteering hoses and

reservoir

looks like this:

Powersteering

reservoir and hoses.

The bracket for the throttle wire was

quite easy... I just took the bracket from the wire to the

cruise

control and modified it a little. Then I took a bracket from a rear

axle u-joint, two bolts

and a hoseclamp, and clamped it to the

tranny dipstick pipe. Sounds awful, but doesn't look

that bad.

Had to fab a connection between the accelerator linkage and the

throttle wire too.

Throttle

cable bracket and linkage.

Couldn't help it, I just had to take

another shot of the engine compartment. Now it starts

looking

like something useful...

Engine

compartment, front view.

I also got a stab at the front

brakes. Nothing much to be said about them, new shoes and

new

cylinders, cleaning and a wheel bearing adjustment.

Front

brakes.

That pretty much sums it up for this

update. Will try to do more work and update after the

upcoming

weekend.

Well, the weekend came and went. I

was occupied with domestic stuff, like birthdays and

such, so I

didn't do anything. But hey, there was another weekend coming and

this time I

got some stuff done!

I rebuilt the master brake cylinder

so I can have some brakes on the old girl. Just have to

bleed

them, which I'll do when I remember to dig out the brake bleeder from

its hidings.

I also gave the vacuum booster a touch-up. I will go

for a hydraboost setup when I can

dig up the cash needed, or if

the vacuum boster is gone to the dogs. But that is a later

story.

Here's a picture of the fixed up combo....

Looks

okay I think. A wire wheel on the angle grinder works wonders....

I also got started on the second

battery shelf on the passenger side. With the 6.2 I need

dual

batteries, which is a lot cheaper than a single huge diesel battery.

I measured and cut

out a hole in the passenger side inner fender

to accomodate the battery shelf. Picture time!

Cut

out seen from the wheel well.

Bent and welded some sheet metal,

added reinforcements, and welded it in place.

Looks pretty okay, I

think...

Battery

shelf welded in place.

A little black roofing paint makes a

pretty good rust protection. This paint is heavy and

has a very

high solids value, 67%, which makes it perfect for rust protection.

First

coat applied...

Another obstacle of getting further

with this build has been the steering column, or the

lack of a

steering column, to be more precise... Now that is taken care of as I

found a

nice one from a Chevy van in the junk yard. Got it

complete with everything needed.

I have to do some re-wireing

though, as the multi-switch on the column for the wipers

supply

ground to the wiper motor on the chebby. Two relays will take care of

that.

Steering

column from a '89 chebby van.

Had to move the firewall mounting

bracket up 1½”, and change the angle a little

to make

it fit. Also had to make the slot for the steering column in the dash

a

little wider. I love that angle grinder!

Here's how it looks

when loosely mounted with some wire.....

Steering

column and wheel in place.

One thing I have to deal with before

fabbing the mounting bracket for the column is

that the hi/lo beam

switch on the column interferes with the pedal/column mounting

brackets. I'm inclined to ”rednecking” that problem

with the angle grinder. But We'll

see...

Turned out I didn't have to redneck

the hi/lo switch. Just trimmed the plastic and bent

the

connectors a little, and voilá! Been busy working on the truck

and haven't rememberd

to bring the camera, so pictures are coming

later.

So, I've done the brackets for the

steering column. I used the original ones and welded

on some ears

for the column and distances to the mounting brackets under the dash.

Upper

steering column bracket.

The steering column is finally in

place and secured. I also had to fab the piece between

the

steering column and the steering gear, not that it was much of a

problem though.

I just used the lower part of a Volvo 740 steering

shaft and fabbed an adapter between

that and the Mazda steering

gear. I also cut 6” from the upper Volvo steering shaft to

get

the Volvo lower shaft connected to the Chevy column. Fits like a hand

in a glove.

Steering

shaft, mostly Volvo parts.

I also did most of the work of

connecting the shifter linkage. Fabbed the link between

the

tranny and the shift lever. Now I just have to decide how I'll do the

pivot point for the

shifter axle at the frame.

Shifter

link at transmission.

Did a little other things too, like

connecting the last hose (vacuum to mastervac) and

mounting the

left inner fender. At last it feels like I'm getting

somewhere...

Picture of engine compartment with my nice dual

battery setup....

Starts

looking allright!!

There's still some minor things to do

in there, like taking out the choke wire, mount a windshield

washer

tank, and finish up the electrical stuff. Maybe some last minute

touch-ups too....

Well, today I got the tank in place,

and fixed the last things with the filler neck, vent, and fuel

hoses.

Also rigged the return hose from the injection pump. More work than

anticipated, but

it feels good to have it done.

Then there's the thing about

connecting the column wiper/washer switch (and its electronics)

to

the IH wiring. And the turn signals, and the key switch. No worries

though, I have that pretty

much figured out. Good to have

complete service manuals for both chevy and IH....

The last few weeks have been filled

with domestic things, like tiling the groud floor bathroom.

And

ofcourse my old friend Murphy stuck up his ugly head from the hole

where I last stomped

him down... The fuel shutoff solenoid in the

injectionpump on my chebby van broke down. Had

to ”borrow”

the one from the 6.2 in the IH. That sucks.

On the bright side, I've got the

engine running after its two years rest! It was a lot of work

to

bleed the air out of the fuelsystem, all the way to the

injectors. I even had to give it a a small

dose of ether to get it

to fire up. Well, anyway, it runs but the injectionpump is leaking so

I

guess I'll have to take the biscuit and get a rebuilt one.

At last I took the courage to start

applying bodylead to the fenders and the front cowl. I

haven't

worked with body lead in 15 years, so I was somewhat rusty in the

technique of

applying it. But the result was pretty okay, I think.

Picture time!!

Right

cowl, left cowl, right fender, and left fender, with body lead

applied.

So, another week is gone by and a few

things have happened. Front fenders are in place

and the front

wheel wells have gotten their layer of rust protection. I had to do

something

while waiting for the Easter holidays to end so I can

get my remanufactured injection pump.

Oh yes, I removed the

injectionpump, no pleasant thing to do. Mucho worko....

The

Stanadyne DB2 bad, bad, bad injection pump.

Not to get too gloomy, let's take a look at the fenders and other stuff...

Right

and left front fenders in place.

I did give the fenders and the inner

wheel wells a good spraying with rust protection

before I mounted

them. Thick black goo that never dries up completely and is a h*ll

to

get out of the hair, once it got there....

Inside

right and left wheel wells. Fuel filler visible on the right.

I also did some electrical work.

Cleaned up the auxillary electrics they put in when

it became an

ambulance, i.e. ripped the wires to sirens and flashlights. I also

had to build a new fuse panel, and at that point I decided to

incorporate the two

extra fusepanels for the ambulance stuff into

the new glove box mounted panel.

The fuse layout is the standard

IH, at least the upper five fuses on both sides.

Lower three

fuses on each side are custom. Looks quite nice, eh?

New

fuse panel.

I also assembled the wiper controls.

As I stated before, the chebby electronics

provide ground to the

wiper motor which is on a constant hot feed. Exactly the

opposite

of the IH. Qute. So, I had to come up with a two relay design to

interface

the two. Oh, by the way, the IH wiring of the wiper

motor is a little weird.

Green wire is the park lead, always

hot.

Black AND red wired together to + gives slow speed.

Black

wire to +, and red wire open gives high speed.

Well, when I got that right it was no problem. Looks like this:

Wiper

control box and interfacing relays.

Well, just had to update with a

picture of the new injection pump. I was lucky to get the wrong

pump,

a 4520 instead of the 4503 that i returned. Better pump, used in

military applications

and HD trucks. Looks like this when I

finally got it in place:

The

new budget buster...

Lots of things have happened since

the last update. I've been too busy to fixup this page,

but I'll

try to get some of it done now. No pictures available yet, but I'll

do that too, later.

First of all, I finished installing

the new injection pump. Whoa, what a pain that was! The

fuellines

don't install easy... But I got it started... After a few days of

intense work.... I had to

remove the mechanical lift pump and

install an electric at the tank. Oh, did I mention that the

tank

had a couple of small pinhole leaks? So, down with the tank again,

flush it with acid and

seal it with polyurethane paint. So, now

the tank is bright red inside... Nice!

Well, at least it runs. First it ran

like crap, hopping and bobbing, no idle, and a bad smell of

unburned

diesel. Found out that one injector was loose. After tightening it

the engine runs

smoother, but still not 100%. Will tune it

later...

I've also sprayed rust protection inside all hollow places, like rockers and A,B, and C posts.

Now it's down on its own wheels! And

it moves. For now it has been driven a couple of yards

back, and

the same distance forward. Not much, especially when considering that

it is what

it has been driven over the last 25 years!

She's

outside! By her own power!

Found out that the radiator was

shot. It looked good, and seemed good until antifreeze

started to

pee out of the cells when the level approached the ”full”

mark... Time for a re-core!

Brought the rad to a shop yesterday,

and will be getting it back Friday. Another budget buster.

So, what to do while waiting for the

radiator? I hate waiting. I started on the interior...

First thing

was to toss the seats, them old '60-ies Volvo seats looked fairly

good, but I want

something more comfortable. Will go junk yard

hunting for seats pretty soon. Anyway, with

the seats out, I

trashed the old center console, enabeling me to get the floor mats

out.

This revealed some floor rust, but nothing serious. A few

strokes with the wirebrush on

the angle grinder took care of

that, and then two generous coats of white roofing paint, to

make

the floorpans like new and protected for ever...

Guess it is time

to go shopping for materials for a new center console, and some sound

proofing stuff. Me likes a quiet ride.....

Roofing

shingles as sound proofing material!

Roofing shingles are the same

material as the expensive sound deadener plates that

you can buy

at automotive stores. Except they have that coating with sand, and

they're

a lot cheaper. I will pad the shingles with some closed

cell foam before the carpet goes

on.

I've also ripped out the divider

between the driver compartment and the back. Very solid

thing,

made of ¾” plywood, polsterd

with foam, and clad with ugly green vinyl. I retained

the lower

10” of it, and the upper 6” of it. In the lower part

there is the aux heater, and the

front seatbelts are anchored

there too. The upper 6” contain a nifty locker, using the space

above the front seats.

Got the radiator back from the

radshop. I had them recore it with a 3 row core, instead of

he

two row original one. Had to haggle a bit to get the price down to an

affordable level...

Anyhow, it is installed and it seems like it's

holding up.

Well, well, well... Time for a new

update! I haven't been feeling so good these last weeks

and thus

not done so very much. Anyhow, I have done the new center console,

and painted

the pieces that I left of the divider between the

driver compartment and the back with

black vinyl paint. I just

can't stand that ugly green (I call it ”prison green”)

color.

Black is beautiful though.... Picture time!

Center

console, padded and clad with black fake leather.

Still missing

the doors for the storage bins.

The center console is made of ¼”

plywood and has space for a switch panel, radio/cd,

dvd

player/back-up camera monitor. Plus cup holders and lockable storage

facility.

Quite nice, if I may say so.

Ah, just for shit and giggles, here is the junk pile my mom is pissed off about...

One

of the small junkpiles...

Well, time has passed and I'm still

not very far in the paint job preparations.

That might be because

I've all those domestic things to do for my upcoming

5:th wedding

anniversary... Got a long list from the significant other, and

that

means no play in the garage.

But on

the other hand, I've at last gotten off my big butt and orderd a

hydraboost

brake booster. During my short excursions with the ol'

girl I quickly came to

the conclusion that the vacuum booster was

shot. Or the vacuum pump, or both.

Best thing to do? Convert to

hydraboost! Can't wait till it arrives!

So, the

hydraboost has arrived and is in place. Ofcourse I forgot to bring

the

camera, so pics will be of the booster installed.... Here

they are:

Right

and left view of Hydraboost and master brake cylinder.

As you

can see, I used the mountingplate from the '99 Suburban the unit came

from, and just drilled two new mounting holes. The new ones are

the lower ones,

that center together with the large hole for the

pushrod.

The pushrod was about an inch short so I had to weld on

an ear to make the brake

pedal get to the normal height.

Otherwise there were no big problems.

Hoses are also from the

suburban. I had to rebend the preassure hose at the

pump

connection, and change the OEM fitting at the steering box end to a

banjo.

Paintprep

is coming on fine though. As the lazy bum I am, I got me some

help

with the most boring parts of the prep work, the sanding. For

a while I have my

personal little 19 year old slave, who is very

good at saying ”Yes massa”, ”No

massa”,

and ”F*ck you massa”. He's quite good though, and with a

little

practise he could be a good bodyman. Some pics to show

it....

Sebastian

(a.k.a. the slave) with the disc sander...

The roof

has curves that go in all kind of directions so it is extremely

difficult

to get a nice, even finish on it. It takes a lot of

sanding, and a lot of applications

of filler to get it right...

Paint

prep coming on nicely...

When we

thought that the roof looked okay, it was time to shoot some primer

on it. I used a marine application epoxy primer that probably

will last forever.

A good thing with epoxy primers is that you

can use bodyfiller on top of it if

neccesary, whereas you can't on

a washprimer.

This is how it looks with the roof primed....

Roof

primed. Got quite late that night....

Looking

at it in daylight revealed some small blisters, and a couple of

places that

need more filler and sanding... Good thing I used an

epoxy...

Haven't

done much lately besides a little bodywork, but I have kept busy in

finding

parts for a front disc brake conversion. It will happen

when I get all the parts together

and have the time to do it. Will

do a complete write-up on the conversion and post

it here and on

the Binder Bulletin.

So, today

I finally put some paint on the top. Bright red. Just the right

ambulance color!

It didnt turn out as good as I wanted, but what

does? Atleast it's nice and shiny, with

a couple of dead bugs in

it. As for a garage paint job, it turned out fairly well.

These

couple of pictures got snapped by my sister. These two first ones

without my

knowledge (until I saw the flash...). Let's see how

they come out....

Me

at work... After painting you have to clean the gun. God am I getting

old... :)

So, how

did it turn out? Well, there's a pic of it while drying... The second

picture is

what my sister scooped off the top of the outdoor

fishtank.... If her fishes die, she'll

probably hate me...

The

dome that's on the hood is the cap for the ventilator on the rear

part of the roof.

Nice

new shiny red top on the T'all... Not so nice red stuff on top of

fish tank...

So, it's been a while since the last

update. Not that I haven't been busy fixing things

on the old

girl, but those things don't show up on pictures. But today, finally,

I've shot

the primer. Some minor visible scuffs are still there,

but I will attend to them tomorrow.

Front

and rear pictures when primed.

Well, two more pics to go... Looking

closer at the primer revealed some spots where

the primer had

reacted with the surface and loosend a bit. Nothing much. Worse is

that

I got the dreaded orange-peel, which means that I have to

wet-sand the whole thing!

I really, really hate it! That's for

testing out a new primer that I had never used before.

Left

and right side pictures when primed.

At least I didn't make anything run

away in the primer. So, I guess it's just to start the

wet-sanding

and shed a tear or two...

Six hours of wet-sanding... Finished!

But it took its toll on my hands. Now they look

like the hands of

a cleaning lady, with the skin worn down so far that two of my

fingertips

started to bleed. Not funny at all....

Anyhow, now it's ready for a wash

with prep-sol and then the final coat of paint! This will

happen

this weekend, that is if I'm not getting some time and do it on a

week night....

Shot the paint today... Phew! There

will be pictures after the weekend as I don't have

time to take

them right now, not to mention that I (as always) forgot the camera

when

I went out to do the work. From what I could see half an hour

after shooting the final

coat, there are a couple of ”run-aways”,

but those will be easily fixed with some 800

grit wet paper and

some polish. I just don't do this often enough to be able to shoot

a

perfect paintjob...

So, let's see some pictures!!

Looking

good from the front... Engine compartment not messed up either...

Not

too bad at all, eh?

Okay, two more pictures, then we call

it the day. Still lots of things to do, like all of the

interior,

assembling the exterior, and getting 'er inspected!

Now there's a little more to do

paintwise, a few toch-ups, some small spots to wet-sand and

polish,

and a some places to use rubbing and polish... But all in all, she

looks a lot better now

than when I brought her home!

Time passes and she's coming together

piece by piece. No pics yet, but now she has gotten

tail lights,

front lights, turn signals, and a front bumper. Still looking good,

or even better and

better... Have some pics....

Front

and rear pictures, notice working taillights!

Today it hasn't happened much, just

threw all the junk out of the back of her, and started on the

interior a bit. That is, I emptied a can of black vinyl paint

over the ugly green stuff back there...

It'll take at least one,

maybe two more cans before all the green is gone...

Well, not much has been done the past

weeks. Mainly because we got two new puppies, and

there really

hasn't been time for anything else than getting them house trained.

Some small

things have been done though... Sound proofing of the

rear floor, some electrical gremlins got

straightened out, and a

chebby van back seat has been modified to fit.

One gremlin was

the light switch. Broken, and no doe for a new one. So, what to do?

Well, I cracked it open and fixed it with some superglue... The

connectors were loose and

just fell into the switch when it was

pulled out.

Anyhow, I'll take some pictures of

the minimal progress as soon as I remember to take the

camera to

the garage...

So, it has been Christmas... There

was no way for Santa to fit a Scout down my stocking, but

my

sister didn't hesitate to use her imagination to get me the best

Christmas present this year!

She made me a ”Travelall

Emergency case” that I just have to share some pics of...

The

ultimate X-mas present! A Travelall Emergency Case.

What about my Travelall... Has

anything happened? Oh YES!

All lights are working, All major

things needed for the safety inspection are there. Now it's

time

to get insurance and a safety inspection. Pics will follow later

today....

Yes, today is picture time again, and

while this ”today” is a few days off from the ”today”

in the last paragraph, I'll throw in a couple extras.

So, I took her for a small test drive

today... Almost everything is honky-dory, just have to

do some

minor adjustments and fill some ATF into the tranny. It's slipping,

and oil level is

quite low. Oh, another thing that has to be done

is to spray some rust protection inside

the doors and on a few

places beneath.

Lets have some pics!

It

was getting dark but these pics show working lights...

Starts

to look good, both outside and inside... Should be enough space for

the dogs...

The back seat is a slightly modyfied back seat from my

chebby van.

Still

a little to do here, but that'll happen later.

Did some small things today like

spraying rust protection inside the doors, and

measure up the

side view mirrors. The mirrors, by the way, are West Coast style

and

need to be narrowed about 4 inches to look good. Pics are coming!

I also got the old girl insured, got

it registerd for road traffic, and got an appointment

for a safety

inspection. The date is set to February 1. May the force be with

me...

Oh, just remembered... I have to take

a look at the windshield wipers. They make

an awful lot of noise

and behave slightly erratic. Well, plenty of time for that....

Time flies, and I've finally gotten a

job (part time), so things haven't moved along as

fast as I would

like.... Had to make new brackets for the side view mirrors, but now

as they're finished all there's left to do is mounting them and

the mirrors. The recepie

for new brackets for west coast style

mirrors is:

One angle grinder, A drill press, A hack saw, and four

Volvo door latches.

Pictures later...

Still on the to-do list: Brake

adjustment, brake test, driving lights adjustment, and a

quart or

two of ATF for the tranny. It will be ready for Feb 1.

Finally some pictures! Had to borrow my sisters camera as I, as usual, forgot mine...

Just

missing the hub caps and some minor trim.

Side view mirrors in place, brakes

adjusted, and two quarts of ATF filled. Still needs

a couple of

quarts... Have to buy some more tomorrow!

Oh, by the way, for those of you who

like videos, here are two short clips courtesy of

my sister Nina:

Getting

out of the den...

Passing

by...

So, today, the first of February, I

went to the dreaded safety inspektion. She almost passed,

hadn't

it been for a couple of minor things. The horn decided to die over

the night before the

inspection, and I hadn't time to fix it as

the inspection was at 06:50.

The right rear door decided to lock

up completely and refused to open.

Right front brake hose is

routed badly.

The dimmer switch on the steering column needs to be

adjusted.

The steering gear mounting bracket needs to get beefed

up, as the gear moves slightly.

Five small things, of which three

really should have been fixed earlier. Mea Culpa.

Anyhow, I got a

month to fix it and re-inspect. No big deal.

There's still some detailing to do,

so this page will still be updated. More pictures are coming,

But

Halleluja... At last I can drive it without looking over the shoulder

for the boys in blue...

So, safety inspection is passed, and

I got the sticker telling that it is inspected and all taxes

(what

tax? She's tax exempt) are paid. Right now this old girl is working

as my daily means of

transportation and she does that well.

Yesterday I went for a roundtrip of about 200 miles to

pick up

some stuff for my other IH, the battered bitch... Got about 24 miles

per gallon

(10 litres/100 km) and that's pretty good for a 2.2

ton brick at 75 mph.

I also picked up the hub caps, and

got some weather striping on her. No more gulps of rain

water

sloshing in when I turn, and much less wind noise from the doors.

Pics right here...

Hubcaps

do a difference, and so does some rubber!

March 16, the day the old girl got

its new shoes. Not really like Cinderella, no nice glass

shoes.

She's a little more macho than that, so she got four new Cooper ATR

in the size

235/75-15, reinforced, 6 ply rated tires. All of them

mounted on the freshly painted steel

rims that hosted the totally

worn out , cracked, and molested Michelins that came with her.

Now

she rolls nice and smooth! Me likes!

March 19, had to get a new

alternator... Ofcourse I had forgotten what a hellish task it is

to

change the alt on a 6.2. On the other hand, I'm happy it wasn't on a

chebby van, they're

even worse to work on. Anyhow, after an hour

of cursing it was done

July 4. This was a bad day for the

old girl... I rear-ended a cop car with her. Not really a good

thing

to do, but when doing a thing like that, why don't do it proper...

Pics below.

The

joint between front and fender measured 10 inches further back than

before....

Here

you see the damage even better...

And before you ask, YES, I had a

bumper in place. Sadly I didn't hit the other guy square,

then

the bumper would have protected the sheet metal much better. Pics of

bumper below...

Bumper

got it as bad as the sheet metal. Pretty twisted, huh?

There's nothing bad that doesn't have

something good in it... Now I get to do those small

things that I

should've done a long time ago. And, as I have full coverage

insurance, I'll get

a wad of cash from the insurance company to

cover the damages.

The sad part is that I can't do much before

they're finished deciding what and how much

they'll throw my

way....

Aug 3, 2007.

Well, the insurance

company seems to stall things and I have no time to wait any

more...

I've started to fix the old girl and am making good

progress. I'll have to hurry a bit though,

because Aug 18 I'm off

to a gathering of old trucks, and a few days after that the old girl

is probably going to be used in a movie... This is severly cool!

Aug 7, 2007.

The insurance company

has inspected the old girl and I get a bag of shiny coins. Enough

to

make a small profit as well as covering the damaged parts. Not much,

but I'm happy.

Aug 10, 2007.

Yippie! Now she's

rolling again. Drove her home again and almost everything is

peachy.

I still need to find a nice bumper and a new beezel for

the right hand driving light. But I think

I'll manage to do

that...

What an awesome feeling it was cruising the freeway

again!

Aug 11, 2007.

The old girl just

died on med today.... On the freeway. Seems to bet the fuel shut off

solenoid

that has gone south, and that's a very odd thing

considering the injection pump is newly

rebuilt. It's just been

there for 18 months or so, so I'll complain loudly to the rebuilder

tomorrow.

Aug 15, 2007.

Well, it wasn't the

fuel shut off solenoid. The whole pump has seized and the axle in it

has

broken. This means I'll have to get another pump... I'll pick

it up tomorrow and spend the

night installing it....

Aug 18, 2007.

Went

to one of the largest gatherings/show of old trucks here in Sweden...

Pärlrallyt. Had a

blast and met a lot of new interesting

characters. Very nice, very well organized, and we had

a nice

drive through the country side. Pictures located right

here...

Aug 21,

2007.

Well, today the old girl was in a movie! Really cool, and a

very nice experience for me. Met

lots of nice people and got a

good insight of how it is on the set.

Pictures on a separate

page, right

here....

Feb 20, 2008.

Long time since the

last update, but the old girl has done good service in the mean time.

I've

also been busy with other stuff, like Xmas and birthday

number 40 of my significant other.

So, a couple of weeks ago one

of the bolts holding the starter broke. Had to tow the old girl

back

to the garage and drill out the broken bolt. No fun at all as it was

a 12.9 quality bolt.

Thus no pictures of it.

While at it I also changed the left

side strut rod bushings. The old ones were just junk as you

can

see in the picture below. But after 40 years I think it is okay for a

rubber bushing to be

worn out.

Old

and new strut rod bushing. Click on images for a better view!

I also swapped four injectors to new

ones. This made quite a difference in how that old engine

runs.

Now its quieter and smoother. Still four more to go and with some

luck most of the noises

will go away.

Mar 1, 2008.

Swapped the other

four injectors and it made quite a difference. Now she runs smoother

with

less noise, and starts better too. Still some work to do with

sound proofing, have to fab a sound

baffle under the dash and

then it's all the window seals.... Well, that'll happen, but not any

time

soon. Sadly, but true.

June ,26, 2008.

Nothing much has

happened to this old girl, but that will change soon. She's doing

good

service as my daily driver but a little noisy and nu fun to

fill her up with fuel. It spews over in a

second and it feels

like it takes all day to fuel her up.

So, upcoming changes are:

- Newer

engine (1991) that is a lot quieter.

- Newly rebuilt TH700R4

transmission.

- New 30 gallon fuel tank in the rear, between frame

rails.

- Custom filler neck molded into the rear quarter.

- All

new gauges from Dakota Digital.

Engine and tranny is the first thing

to happen, hopefully in a few days. The new fuel tank and filler

needs some custom work, like narrowing the tank two inches to fit

between the frame rails.

July 1, 2008.

Started out on the

engine/tranny swap today. Or really, I started a couple of days ago

when I got

the old girl into the garage. Anyhow, I was thinking

about removing the tranny from underneath and

just remove the hood

and lift the engine straight up. Today, after getting the tranny off

I realized that

I would never get it re-assembled again this way.

Too many things that are too tightly fitted and I'm

not a very

tiny guy...

So, I had to take the biscuit and remove the front

clip. I wish I had done it when I started the swap, it

would have

saved me a lot of time and frustration.

Looks

kinda familiar? Been there, done that...

With the front clip off, less than 30

bolts and only half an hours work, everything is accessible and

it

will be a breeze to get the engine out, and the new engine and

tranny in. While engine and tranny is

out I'll clean up the

electrical system even further, and I'll install a manual glow plug

system instead

of the magical electronic piece of junk that

resides there now.

Aug 6, 2008

Been working on the

old girl on and off and thought it was time for an update... Engine

and tranny

swap is now complete, as far as the heavy stuff is.

Some details are still in the works like a new

water pump. The

old one developed a nice leak while the engine sat on the floor for a

while.

Dumping the the engine and tranny in

was no big deal. Changing the tranny mount was easy too.

But the

new tranny mount was a little different than the old so I had to shim

it to get the tranny in the

right place. This resulted in the fan

hitting the fan shroud, so I just took it off. Taking off the fan

shroud

made me have to move the power steering reservoir as it was

mounted on the shroud... Well, I guess

you get the idea...

The new glow plug relay (really, a

ford starter relay) is in place and hooked up. Now, as the lazy bum

I am, I have to build a timer for the glowplugs. As I have the

self regulating AC60G glow plugs, it will

be a pretty simple

device that just gives about 10 seconds of glow when ever the key is

turned on.

Maybe I'll add a temperature sensing device later.

Really, I should do it now as it's only the fitting of

a NTC

resistor in the timing circuit... I am a lazy bum...

As the new tranny has an electronic

VSS (vehicle speed sensor) and the speedo of this old girl is

mechanic, I will have to tuck those new gages in now too. Most of

them are in already but the speedo

is left to do. It has to be

calibrated by driving exactly one mile, so I'll have to measure that

distance up

on a quiet road and calibrate. Wires for the new

speedo are in.

In the end it's probably worth all

the hassle it has been. I have had her started up with the new

engine,

and boy does it run sweet! Though it took a whiff of ether

and an over night charge of the batteries to

get it started...

Tomorrow I'll probably sneak out of

work and start tearing off the leaking waterpump... If all goes

well

I might even get the new one installed!

August 8, 2008.

Nothing much to do

at work so I used my lunch hour (and a little more) to tear off the

broken water

pump. This is no easy task on those 6.2's... It

includes removing the power steering pump with bracket,

the

alternator with its brackets, and the timing cover plate as the water

pump also is bolted from the

rear side of that plate... And the

oil filler tube, and some minor stuff. Anyhow, the deed is done.

August 10, 2008.

Finally I got the

new waterpump installed, and a few other things done too. New gauge

cluster is

installed and the new speedo is calibrated. Looks

quite nice!

Not

the best picture but you get the idea...

A push button for the glow plugs is

installed. Completely manual system, as the timer I built didn't

work

as I wanted it to. The timer works, but my intention was that

it should activate it self every time got a

12 volts feed. It

didn't, so I have to re-design it... Anyhow, the glow plug system

works.

I also did a short test drive with

the new engine... This engine rocks!! I never thought it would be

so

much difference between the old beater 6.2 and this newer

engine with only 200.000 miles on the

odometer. With this engine

you have to be very easy on the throttle...

Still left to do before I'll consider

her drivable again is to check the power steering hoses and to

mount

the front bumper.

After that I'll start measuring and thinking

about the 30 gallon fuel tank, but will have to wait a while.

September 6, 2008.

Just a minor

update this time. I did some basic maintenance today, like a new fuel

filter and checked

the basic fluid levels, getting ready for the

2nd Annual Johnnie Reb Run next weekend. Still need to

check transmission fluid level but I'll save that for tomorrow

when I'll take her for a longer test drive.

November 21, 2008.

Today I gutted

the fuel tank from the ”Battered Bitch” to seal it off

and put in a slosh guard for the

fuel level sender. I found that

there already is a slosh guard for the fuel pick-up, but the fuel

sender

is outside of that, so I just bent some sheet metal into a

new one and welded it in place.

The new digital instruments fuel

level gauge really needs this as it is too sensitive... It jumps

between

full and empty like crazy when fuel level drops below 65%.

The fuel tanks shape does not help this

either, as it is narrow,

thin, and very long... Enjoy the pictures!

Fuel

tank and a close up of the new slosh guard.

The tank itself is

in great shape, except for a couple of holes from when someone used

too long

screws in a couple of places. Well, the magic welder took

care of that, and everything is sealed

up with body lead so there

should be no leaks anymore....

December 13, 2008.

The old girl

finally got a nice pair of new shocks. It was a pain to get them,

they were not cheap, but

they were a breeze to install. Now she

handles a lot more comfortably and feels a lot safer to drive.

Januari 13, 2009.

Just a short

update to remind myself that I'm alive and have to do some work on

these pages agin.

Or, rather, do some work on the old ambulance so

I can make a real update again...

The old girl has made real good work

as my daily driver this far and it is soon time for the bi-annual

safety inspection again. I don't think there will be any big

issues, I'll probably just have to fill up the

winshield washer

and adjust the running lights to pass. But one never knows...

Upcoming things on the to do list are

to change out the clutched fan to a smaller flex fan. This is so I

can get the right angles on the drive shaft. To get there I need

to raise the rear end of the transmission

about an inch and that

would make the fan hit the lower radiator hose. Thus the flex fan. I

got all the

kit I need to do it, so I wonder why I'm not at it

right now.

I also need to get the new fuel

filter assembly installed. This CAV / Lucas filter unit will replace

the

GM secondary filter which is crapping out on me by starting to

leak in various places. All I need to do

this is a couple of hose

barbs and I'll try to get them today.

New

Diesel filter assembly and hose barbs.

Oh, I almost forgot... It has been

Christmas! I'll make an Xmas 2008 page and put it up as soon as

I

can... But there are two things that the American Santa brought me

(thanks to my sister for carrying

allt that stuff through airports

and customs. Sis, love ya!).

First off is a spacer for the flex

fan. Strange thing is that I couldn't get one that fit here in

Sweden, no one

seemed to care to stock a spacer with a ¾

inch hole for the water pump axle. But finally I found one and

my

very nice sister agreed to carry it home for me.

Secondly I got a

complete set of weather striping for the doors of the ambulance. This

will also have to

be istalled pretty soon, and as such it is on

the to do list. Right now there's a lot of wind noise and I

like

a quiet ride...

Complete

kit of door glass weather striping.

January 16, 2009.

The old girl

passed the safety inspection today with flying colors!

Not a

thing went wrong, everything was working as supposed, and I had a

nice long chat with the

safety inspectors. Couldn't be better!

There are still things left on the to-do list though, so there's no rest for the wicked!

April 23, 2009.

Today I finally got to strike some things off of the to-do list... I installed the flexi fan, which was a lot more

work that I first anticipated. I had to fab up new pin bolts as it was impossible to use bolts and nuts to fit the

fan and spacer. Anyway, now it's done and it works perfectly. I was kinda afraid it would be a lot louder than the

clutched fan, but contrary, it's quiter. Good thing.

The fan install enabled me to raise the rear of the tranny about an inch, which was just what was needed to get the

drive line angles right. I also found a wheight on the drive shaft that wasn't supposed to be there, and with that

removed the nasty vibration I had at around 65 mph was gone! Nice!

I also managed to tighten up the torsion bars about half a turn. It's a lot stiffer now and that's a good thing

too. Now the suspension hold up much better when going over speed bumps.

So, all in all, today was a great day! Tomorrow I'll probably swap the fuel filter assembly, and, if time permits,

I'll swap the fuel tank too. But I'm satisfied if I get one of those things done...

April 24, 2009.

None of the things above did happen today... Simply because I hadn't the guts to start on a bigger job when I had

to use the truck about in the middle of the time I had to my disposal. So, both the tank swap and the fuel filter

swap have to wait a bit more.

So, what did I do this nice and sunny day? Well, I managed to drain the TH700R4 of tranny fluid, and I managed to

fabricate a special tool needed to take off and put back the servo cover of the TH700R4. Now I only have to fab up

a tool to remove the front oil pump too. This is a simple one though so it shouldn't take long. These tools will

aid me in rebuilding the tranny I have on the floor, which will go into my other Travelall, The Battered Bitch.

More on this subject is coming in the appropriate build-up page ('64 Travelall) later.

April 27, 2009.

Ah, at last another thing to strike off the to-do list... Today I installed the new fuel filter assembly! It was a

heck of a lot more work than I first thought, but alas, now it's done.

To install it I had to remove the intake manifold just to get to the hose connecting the injection pump to the old

filter. While down there in the valley I removed the old OEM fuel line from the mechanical lift pump to the old

filter, and fabricated a new hard fuel line from the injection pump that ended outside the intake runners. This

made the installation of the fuel hose to the filter a lot easier and it's good for maintenance also. Anyhow, the

old hose was just 1/4 inch while the new one is 5/16 inch, so I had to do some fab work anyway...

A short bleed of the fuel system later she's roaring down the road as she should! It was a royal pain to get it

done, but well worth it, considering I now have a fuel system without leaks.

April 28, 2009.

Had a couple of hours of IH time today. Not enough to make the fuel tank replacement, so I started out on the

weather striping that I got for X-mas. I began with the driver side rear side door, and it took me a full couple

of hours to get it done... That is, it's not quite done yet, I still have the outside chrome molding to do. The

reason I didn't get it done is that I knicked it badly while removing it, but luckily I got spares.

The shop manual says "pry off molding" and refers to a blurry picture where someone prys it off with a screw driver

and it looks quite easy. Not so. Anyhow, theres a lot of paint on the spare one and I had no stripper available, so

it has to wait until tomorrow.

Oh yeah, my alternator seems to have crapped out on me also. I might be a wiring issue, like a breach on the

voltage sensing wire, but I'm not taking any bets on that... I've had too many alternators dieing on me to do that.

We'll see tomorrow what gives.

April 29, 2009.

Yep, it was the alt crapping out. Luckily I had one on the other engine, the one that's going into the '64, so I

could postpone the cost of getting a new one. Good thing this is a bigger one, 105 amps instead of 63.

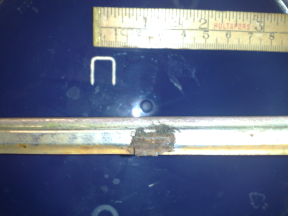

I also did the weather striping on the chrome molding... This is the most idiotic construction I've ever seen. The

weather striping is fixed to the molding with something that looks like over grown stapels, and getting them bent

inside a tiny space in a wimsey chrome molding is just a big pain...

Staples and chrome molding with old staple left.

I will skip doing that one on the other side, it's simply not worth the time and effort to remove chrome molding,

remove old stapel clips, going through hell installing the new clips, and then get the molding on without breaking

it. Won't do that again. Front doors are much easier, regular push trough clips on the weaterstriping there.

April 30, 2009.

Did the other rear side door weather striping today. It only took one and a half hour from start to finish, to be

compared with the five hours it took on the other side. But this time I skipped over the outer seal on the chrome

molding. Guess that did the time save....

More workee tomorrow!

May 1, 2009.

Workers unite! Today we work a day with out pay to make comrade whatever happy... Nah... Didn't think so...

Though I got some things done today anyway. I swapped in the other fuel tank, the one I made a slosh guard in. At

first everything went honky-dory, I made good time getting the old tank out and draining it of the five gallons of

diesel that was left in it. No surprises, everything went fine. I moved the fuel level sender from the old tank to

the new one as the one in it was a bit suspicious and then I started to jack the tank up between the frame and the

rocker. It seemed to fit a lot tighter than the old one and I had a heck of a job to get the hoses on. The filler

hose was the worst, but finally I managed to get it right. So, up with the steel bands that keep the tank from

falling down, and tighten the bolts.

Now we have come to the more exciting part of the job, that is filling the five gallons of diesel back into the new

fuel tank. After two gallons I hear a drip-drip-drip.... Awww.. Shucks. I took a look and saw it was right at the

drain, so I tightend the drain plug. Drip-drip-drip... What the he... Ah, the old copper gasket on the drain plug

didn't look so good... Well, I changed it, no problems... Drip-drip-drip... Uh-oh... [censored]

Looking real close at the area right beside the drain plug I spotted a hole, not even pin sized. The clock was

ticking and I had not time to remove the tank and fix it properly by welding it shut... So, I made a temporary fix

by taking a sheet metal screw, made a gasket of some fuel hose, coated the stuff in Permatex, and screwed it right

throgh the pin hole. Presto, no more leak.

I know I have to fix it permanently later, but not right now. I'm kinda tired of getting drenched in diesel. I'll

take care of it later.

So, how does the slosh guard work? Well, with only five gallons of fuel in the tank the fuel gauge still jumps a

little. Not nearly as much as before though. I'll fill her up one of the coming days and see how it works out when

there's more fuel in it. I think I'll dump in five gallons a time and see what happens.

More to come on this later!

May 4, 2009.

Had a couple of hours free to do something and decided I'd go for a try on the front driver side door. Same problem

as always with rusted bolts and screws, otherwise no big problems. I discovered that one felt channel, the front

one, was a bit too long so I had to cut it.

The lower glass felts wer no big problem, but I had to cut them a quarter inch too.

May 7, 2009.

Did the other side today, no bigger problems than the driver side. Good thing is that I had an opportunity to look

closely into all the doors and they are completely rust free! I like it. Must have done something right when I

sprayed them with rust protection...

Saturday and Sunday I'm off to a meet some 20 miles away. Will be a nice day trip and the weather sounds promising.

May 8, 2009.

Just went out very shortly and did some minor work. That is, I sealed the passenger side air intake in the front

cowl. Will be nice when winter comes, not to have an ice cold draft on your legs...

Rip out the glove box, some window sealer and duct tape did the trick.

I also cleaned the TH700R4 slush box on the outside, making it ready for disassembly.

May 18, 2009.

Slushbox finished, so I can start a little work on this one again. Nothing much done today except ripping the

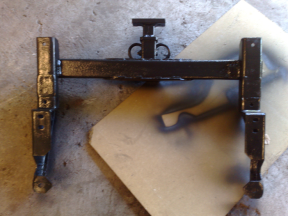

receiver off the chebby van and started to clean it up and modifying it to fit this old girl. I'm gonna need the

towing capability soon, as our other car is up for sale.

Pictures will follow soon. The main thing fitting this receiver to the IH is to narrow it a little, otherwise it is

a perfect fit. I do think I will have to reinforce the frame a little though. I looks a little wimpy at the rear.

May 19, 2009.

Perfect fit? Bah! I really should learn to measure before I talk about "perfect fit"... So, today I cut the hitch up

to modify it. I have to shorten the main bar 5 inches on each side to make the hitch to frame mounting points fit

IH frame. I also have to elongate the pieces that are between the main bar and the frame 3 inches.

Well, I've done the most of the fabrication, now I just have to weld it all together. Thank God I have a good welder.

Hitch, main beam. Shortened to right lenght.

Original bracket and length modification.

May 21, 2009.

Today I almost got the hitch finished before I ran out of gas for the welder. Always happens on a holiday...

Anyhow, I got the pices between the frame and the main bar welded together, and I fit them to the main bar. It's a

nice tight fit and any adjusting has to be done with the tool of choise, the BFH (Big F..ing Hammer). Turns out

pretty nice, just need to adjust the width a little and get it angled straight. Then weld it, then paint it. Then,

I have to get it on the truck, and that may take some time, knowing myself. Pictures...

Assembled hitch, not yet completely welded though.

May 22, 2009.

Finished the hitch today. First I had to drive by the supply store and get a bottle of gas for the welder though.

Now I got a nice, perfectly straight hitch, ready to go on the truck. Just wonder when I'm gonna get that far...

Pics below.

Finished product. Not bad at all...

May 25, 2009.

Just slapped a thick coat of CorroFlex on the welded parts of the hitch today. Now you almost can't see it has

been chopped up and welded together again. When it's dried I'll give it another coat of black, and then on it goes.

June 4, 2009.

This last week I've rewelded that hitch three times! I wish I could learn to tack weld things up and try them in

place before doing all welds and paint the thing. Anyhow, the last time it was just tacked together and then it

decided to be a good fit. At last.

I also wire wheeled and painted the frame where the hitch attaches. Looks pretty good there now...

June 10, 2009.

The last few days I've managed to drill the holes in the frame and test fit the hitch, and today I finally bolted

it into place for good. It's been a lot more work than I anticipated but it looks really good, and the height of

the ball is perfect.

Now I just have to hook up all the electrical stuff and then go get it inspected. Oh, well, I do have to change

one bolt that I kinda trashed the threads on, but that's a piece of cake.

With some luck I'll be able to finally get my other project into the garage this weekend...

Aug 19, 2009.

Crappers! First our other car gets wrecked totally, and now the transmission in this one starts to act up. Does not

shift into fourth, no lock-up, and slips in reverse. I hate it. Got to fix this fast as we need means of transportation.

I will have to get on this ASAP even though I have a honey-do-list that is an arm and a leg long, and just as costly.

Aug 23, 2009.

Switched the transmission during the last two days... As it's almost impossible to do this from underneath I took

off the whole front clip and removed engine and tranny as one unit. A lot easier to do it this way.

While test driving I noticed that it still didn't go into lock-up, and that made me remember that there are five

different ways the lock-up can be wired from factory, and this tranny wasn't wired like the old one. Sigh.

Have to drop the pan and rewire the lock-up circuit... Dang I didn't remember to check this before installing...

Aug 25, 2009.

Dropped the tranny pan today and rewired the lock-up. Bypassed all the mumbo-jumbo and wired it to engage

as soon as the tranny goes into OD. Works like a charm!

Sep 1, 2009.

Finally, after three years of use I installed the stereo. Really, it's only half done as I still have to install the rear

speakers, and the CD changer. But at least there's some music in it now...

Sep 7, 2009.

Finally got some new seats, both front and back. I really wanted leather seats but those available at the local

pick-n-pull were either broken or the wrong color. So, I went with half leather/half fabric and scored some really

nice seats from a Volvo V70. Now I just have to install them too... This will include fabricating some bracketry and

other stuff, but no big things what I know of. Pics will follow...

Sep 8, 2009.

Got the new passenger side front seat installed. Looks great, feels great, but is a little on the high side. Don't think

it's a big problem though, more something to get used to. It was a b*tch to install, had to do completely new brackets

as the distance between the sliders were 4" wider than on the old one, beside the fact that no other measurements

were the same either...

Tomorrow I'll have a stab at the drivers seat. Can't wait to get it done so I can rest my butt in something more comfortabe

than the 42 years old Volvo seats...

Sep 9, 2009.

So, today I got the drivers seat installed. It's a little hig and I gant get it lower without cutting into the drive line hump. Guess

I'll have to learn to live with it, as with so many other things. Hey, this sounds worse than it is, actually the seats are very

comfortable and you have a great view over the ricers infront of you. I'll say it's a keeper. Looks like this....

I do have the matching rear seat too, collapsable, divided 1/3 and 2/3, with 3 integrated shoulder straps. It will be

a lot of work installing it but it will be done. Not today, but in a not too far away future.

This does it for this update. More pictures later! Thanks for looking so far!

Stay tuned! More to come, and very soon too!